Materials

Custom foam fabrication using crosslinked polyethylene foams (XLPE) and other materials.

In fact, we stock a wide variety of materials. We gear our inventory to being able to respond to our customer demand without excessive lead times. More materials may be available but may have longer lead times and minimum buys. Please click here to request your free material sample kit.

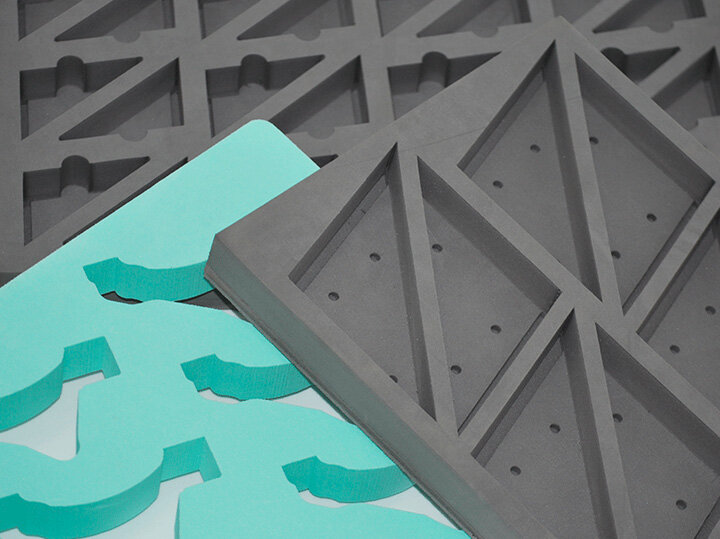

Crosslinked Polyethylene (XLPE)

The crosslinking of polyethylene ties all the polymer molecules together. Because the molecules are tied to together, they aren’t easily torn apart from each other. Crosslinking makes both elastomers and plastics stronger, improving the physical properties such as tensile, elongation, and tear strength.

Continue Reading +/-

Additionally, XLPE offers excellent dynamic cushioning and meets the requirements for “Class A” surface protection. A “Class A” surface is any exposed part of an automobile interior or exterior. The packaging used in the production, handling and delivery of these parts must not affect the quality of the product. We stock a variety of XLPE products from 1.5 lb per cubic foot up the 15 lb per cubic foot.

[

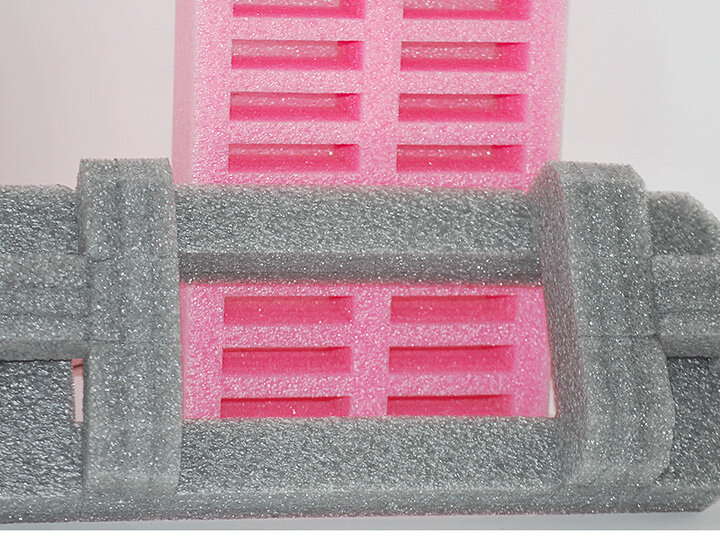

Extruded Polyethylene (PE/PL)

Polyethylene foam is a durable, lightweight, resilient, closed-cell material available in a wide range of densities and colors. It is often used for packaging and material handling applications due to its excellent vibration dampening and insulation properties as well as its high resistance to chemicals and moisture.

Continue Reading +/-

Exemplary Foam stocks a full range of extruded and laminated PE products from l lb to 9 lb. We are also the exclusive distributor of Nomaco Profiles. These profiles provide a cost effective level of protection without the extra step of fabrication.

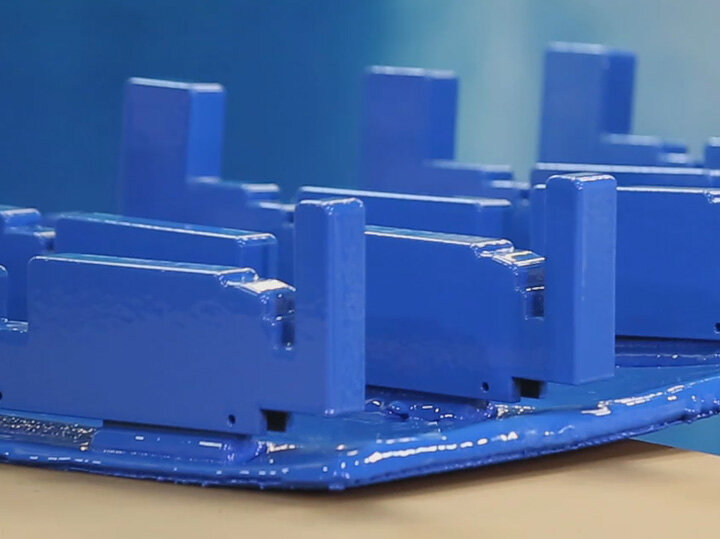

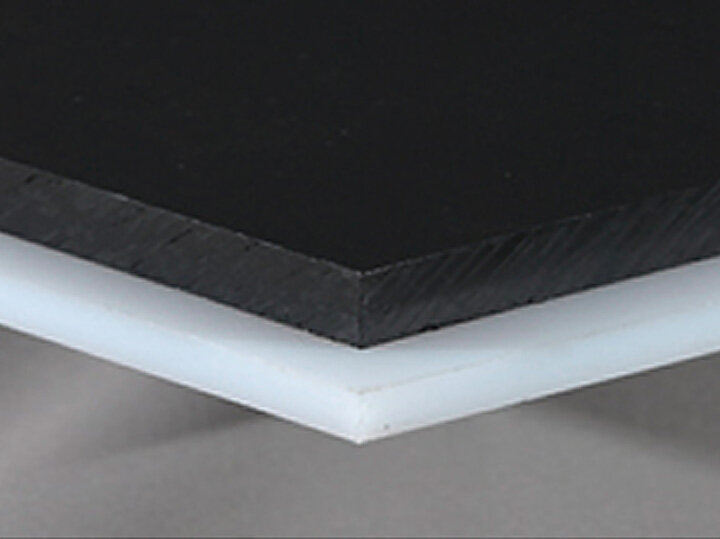

Polyurea Coating (EX 450)

EX 450 is a 2 part spray on coating system with a smooth black finish. It is lightweight, durable and available in many thicknesses. It is resistant to chemicals like acetic acid, brake fluid, gasoline, and jet fuel just to name a few. It meets the requirements of FMVSS302 and is heat resistant to. It can be used inside or outside on wood, metal, open and closed cell foam.

Continue Reading +/-

We can now cut and coat your foam offering a complete turnkey solution, saving you time and reducing costs.

Expanded Polypropylene / Polyethylene (EPP/EPE)

These foams feature a range of molded products often referred to as beaded foam. Expanded polypropylene products (EPP) are used extensively in automotive and packaging applications where durability, multiple impact resistance and other demanding performance challenges must be met.

Continue Reading +/-

Expanded Polyethylene (EPE) is one of the premier packaging foam materials available today. It is ideal for applications requiring resiliencies, non-abrasive surface, and outstanding cushioning . Both of these products offer superior cushioning ability at half the density as compared to extruded PE. Available from 1.0 lb density up to 2.8lb densities, it is an ideal material for many expendable packaging applications.

Pressure Sensitive Adhesives

While there are a wide variety of PSAs available, Exemplary Foam stocks two types for immediate use.

The first is a rubber based PSA for general purposes applications where the bond would not be subject to stress such as high shear or temperature changes. It is available with either a paper or Mylar backed liner.

Continue Reading +/-

The second is an aggressive acrylic based PSA ideally suited for demanding applications of adhering foam to metal surfaces.

High Density Polyethylene (HDPE)

High Density Polyethylene, also referred to as HDPE is manufactured from the semi-crystalline polyethylene (PE) family. It provides excellent impact resistance and durability in high wear environments. Available as thin as .031” it is often used to create parts separators.

Continue Reading +/-

No additional information at this time.