Custom Foam Fabrication Capabilities

At Exemplary Foam, we like to think of ourselves as your “one-stop foam supplier.”

We have a highly-skilled workforce and dedicated service personnel as well as the most up to date foam fabricating equipment available. Because of our custom fabrication services and capabilities, we find ourselves able to respond to a diverse clientele.

Waterjet Cutting

Waterjet cutting is the backbone of our manufacturing processes. Multi-dimensional axis cutting capabilities allow for fabrication of complex shapes out of non-metallic materials. Nesting software maximizes yields, CNC programing reduces setup times and eliminates tooling costs.

Die Cutting

Ideal for high volume repeating items – Exemplary Foam has a full range of die cutting capabilities including kiss cutting of components with pressure sensitive adhesives.

Dieless Cutting

Our CNC flashcut knife cutting system fabricates parts without the expense of dies or tools. Perfect for prototypes, small production runs or where the material is adversely affected by water.

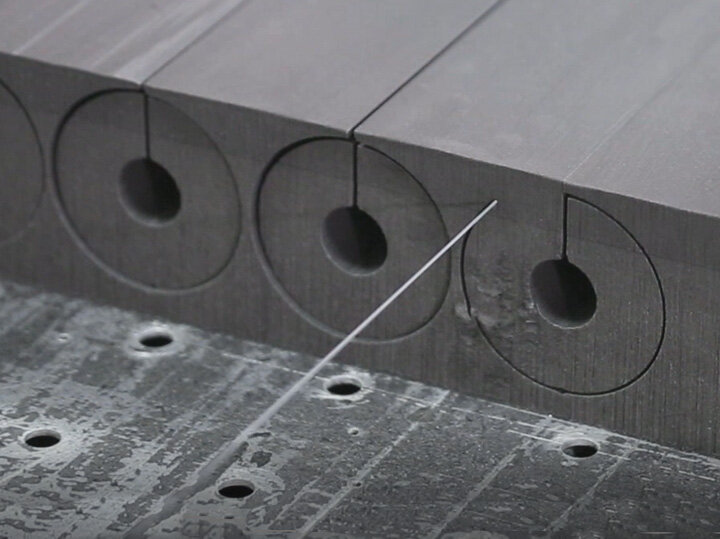

Fast Wire Cutting

Our fast wire cutters enable the creation of complex profiles in a wide variety of materials up to 60” in length. Great for edge protection and pipe insulation applications.

Skiving

With multiple skivers, we have the capability to accurately and efficiently skive materials from low density polyethylene and expanded polypropylene to 15# XLPE. Full sheets split to specific thicknesses are available for purchase as well.

Post Processing

Secondary fabrication processes include t-slotting, shaping, drilling and assembly using glue, hot air or PSA materials.

Routing

CNC Routing allows for incredibly accurate fabrication of solid foam and plastic materials (HDPE & UHMW), providing for multiple depths without tooling costs while eliminating possibility of exposed adhesives.

Controlled Room Environment

Established for the reduction of dust and particulate matter. Employees are required to wear full medically certified protective clothing.

Polyurea Coating

This is a two part spray-on product that provides a protective barrier increasing durability and longevity to a wide range of materials including foam, plastic, metal and PSA tape components.